Home » Pile & Caisson Testing

Pile & Caisson Testing

Caisson Integrity Testing

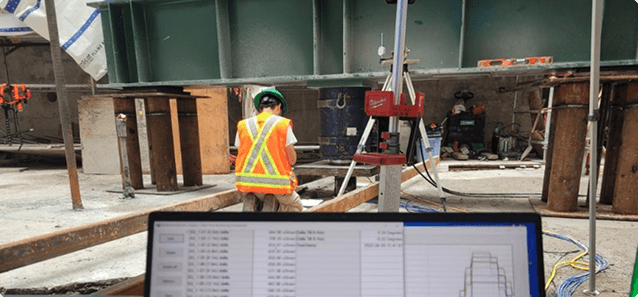

The Crosshole Sonic Logging (CSL)

Method is used to evaluate the quality of the concrete of deep foundations.

Testing is performed with a Cross-Hole Analyzer (CHA) manufactured by Pile Dynamics Inc. During the test a transmitter is lowered down one of the tubes and sends a high frequency signal to a receiver inserted in another tube. The transmitter and receiver move down each pair of tubes, scanning the entire length of the shaft for imperfections and voids in the concrete.

Thermal Integrity Profiler (TIP)

Evaluation of the entire cross-section and the entire length of the deep foundation element measuring heat generated by curing cement to assess the quality of drilled shafts/bored piles, augered cast in place (ACIP)/continuous flight auger (CFA) or drilled displacement piles, slurry walls, barrettes, soil nails, and jet grouted columns.

- Evaluates concrete quality inside and outside the reinforcing cage

- Accelerates construction with tests conducted during concrete curing

- Reveals necking or inclusions, bulges, variations in concrete cover, shape of shaft and cage alignment

The Pile Integrity Tester (PIT)

This method is used to determine whether a pile or shaft is free of major cracks and voids prior to construction of the superstructure. It may be used on most concrete or wood foundations, including piles integral to existing structures such as bridges or towers, and can also be used to assess pile length.

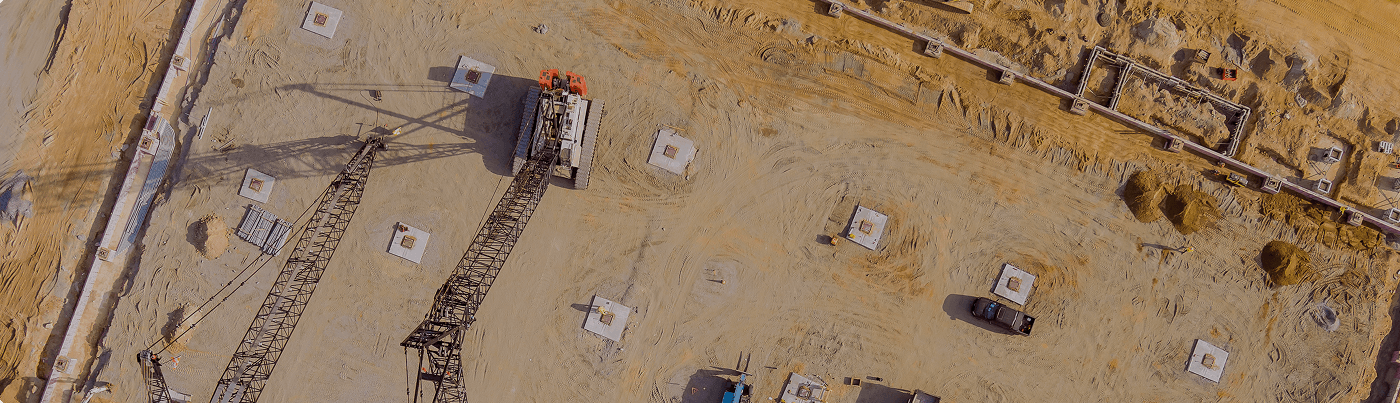

Caisson and Micropile Verticality Testing

SHAPE® is a cost-effective quality assurance testing device used for deep foundations such as drilled shafts, slurry walls, barrettes and more to determine the excavation verticality and profile. It provides superior performance over testing limitations experienced with a sonic caliper due to density of slurry walls.

Pile Driving Analyzer Testing

The Pile Driving Analyzer (PDA) system is the most widely employed system for dynamic load testing and pile driving monitoring in the world. High Strain Dynamic Load Tests, also called PDA tests, assess the capacity of several piles in a single day through a non-destructive technique. Pile Driving Analyzer systems also evaluate shaft integrity, driving stresses and hammer energy when monitoring pile installation.

Caisson Inspection Services

The Pile Driving Analyzer (PDA) system is the most widely employed system for dynamic load testing and pile driving monitoring in the world. High Strain Dynamic Load Tests, also called PDA tests, assess the capacity of several piles in a single day through a non-destructive technique. Pile Driving Analyzer systems also evaluate shaft integrity, driving stresses and hammer energy when monitoring pile installation.

Static

Load Testing

Static load testing is the most reliable method for determining the load–settlement performance and ultimate bearing capacity of deep foundation elements such as drilled shafts, caissons, and driven piles. During the test, a controlled load is applied to the pile—either in compression, tension, or laterally—using reaction systems such as anchors, reaction piles, or kentledge. The applied load is incrementally increased while precise instrumentation (e.g., dial gauges, displacement transducers, strain gauges) measures the pile’s vertical movement or deformation at each stage.

SQUID Testing

- Measures both the thickness of soft material or debris that might be covering the bearing strata, providing force and displacement in numerical and graphical form

- An objective, quantitative assessment is reported through accurate displacement and penetrometer pressure measurements, digitally processed and sent directly from the drilled location to the SQUID™ main unit

Mini-SID

Bottom cleanliness has an important effect upon shaft bearing, shear near the bottom of a shaft, and shaft settlement. Most designers are uncomfortable designing shafts for end bearing and add extra shear depth except when the bottom may be visually inspected. The Mini-SID allows the Owner, Engineer, and Contractor to simultaneously view the shaft bottom whether constructed dry or wet, with water or slurry. This saves time and money by eliminating the need for multiple inspections and allowing the designer to reduce shaft length due to increased confidence in shaft end bearing. The inspections are annotated and recorded for project documentation and later reference.